Workforce Development

Edison State Provides Training for Maintenance Technicians

In today’s tight labor market, finding a qualified industrial maintenance technician can be difficult. Employers can turn to the Industrial Electrical Controls Fundamentals course offered by Edison State Community College’s Office of Workforce Development & Work-Based Learning. This training provides a powerful starting point in developing skilled maintenance technicians from within companies’ existing workforces.

September 4, 2025

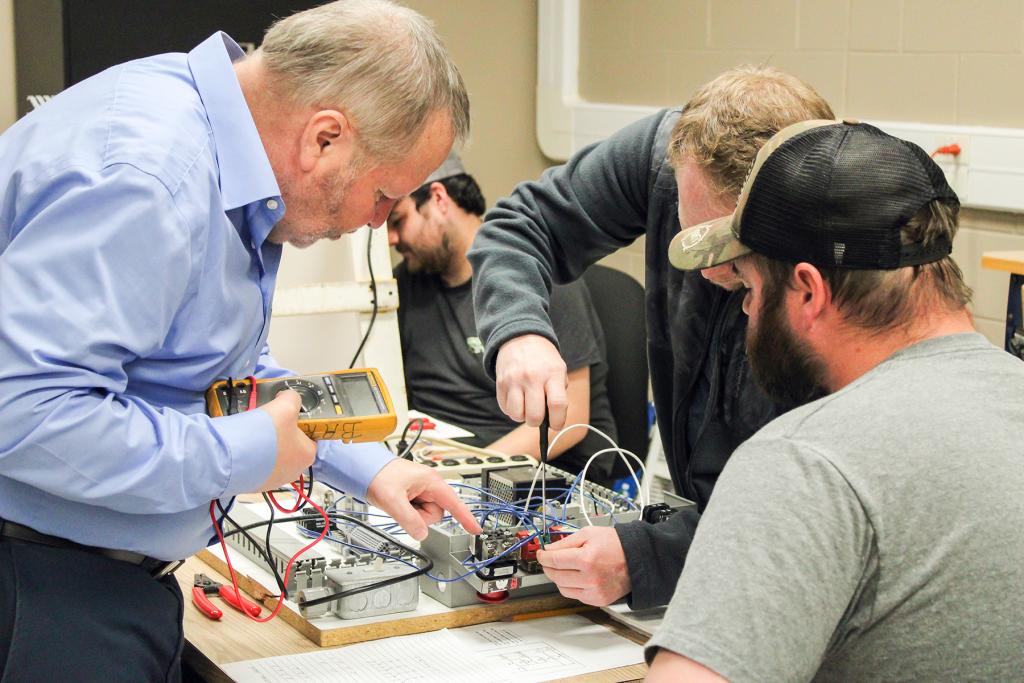

Industrial Technical Training Manager Keith Barga advises Jonathon W., of Cooper Farms (Fort Recovery), and Jason C., of Abbott Labs (Tipp City), during an Industrial Electrical Controls Fundamentals course at Edison State’s Piqua Campus.

“The demand for skilled maintenance technicians continues to grow,” said Keith Barga, Industrial Technical Training Manager at Edison State. “This course helps employers get ahead by turning their dependable workers into highly trained, job-ready technicians.”

Combining classroom concepts with real-world applications, the 32-hour course equips new or transitioning technicians with essential knowledge in troubleshooting, maintaining, and installing electro-mechanical machines. Participants gain practical experience working with industrial control systems through guided lessons and immersive lab exercises. Technicians will leave the course with newfound confidence and competency in a critical area of modern manufacturing.

Topics covered include:

- Electrical safety and standards

- Basic circuitry and components

- Relay logic and motor controls

- Troubleshooting techniques

- Application of control devices

Employers seeking a more comprehensive path to developing talent can look to the Maintenance Technician Essentials program—a robust training track that combines 120 hours of online learning with 50 hours of in-person labs. The nine-month, TechCred-eligible program is ideal for entry-level employees and workers looking to transition into the maintenance field. With small lab sizes, personalized instruction, and a curriculum built in consultation with industry experts, the program prepares students for the real demands of modern manufacturing environments.

Companies can customize course modules to meet their specific needs. Modules include shop practices and measurement, maintenance fundamentals, mechanical systems, hydraulics and pneumatics, basic and advanced industrial controls, basic and advanced PLC programming, and an introduction to robotics.

With a flexible course design, the program allows students to begin anytime, with monthly in-person sessions that fit demanding work schedules. Students also earn college credit and can complete certificates or degrees in areas such as automation and robotics or electro-mechanical engineering.

For more information on the Industrial Electrical Controls Fundamentals course or the Maintenance Technician Essentials program, email Brandi Olberding, Assistant Dean of Workforce Development & Work-Based Learning, or call 937.381.1533.